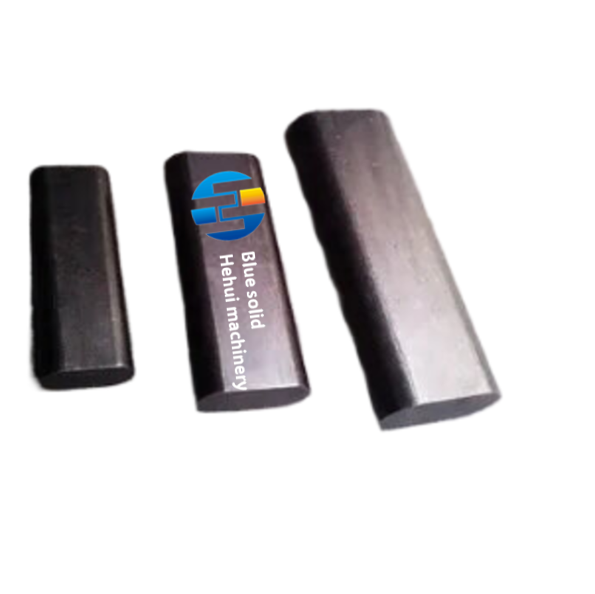

棒销

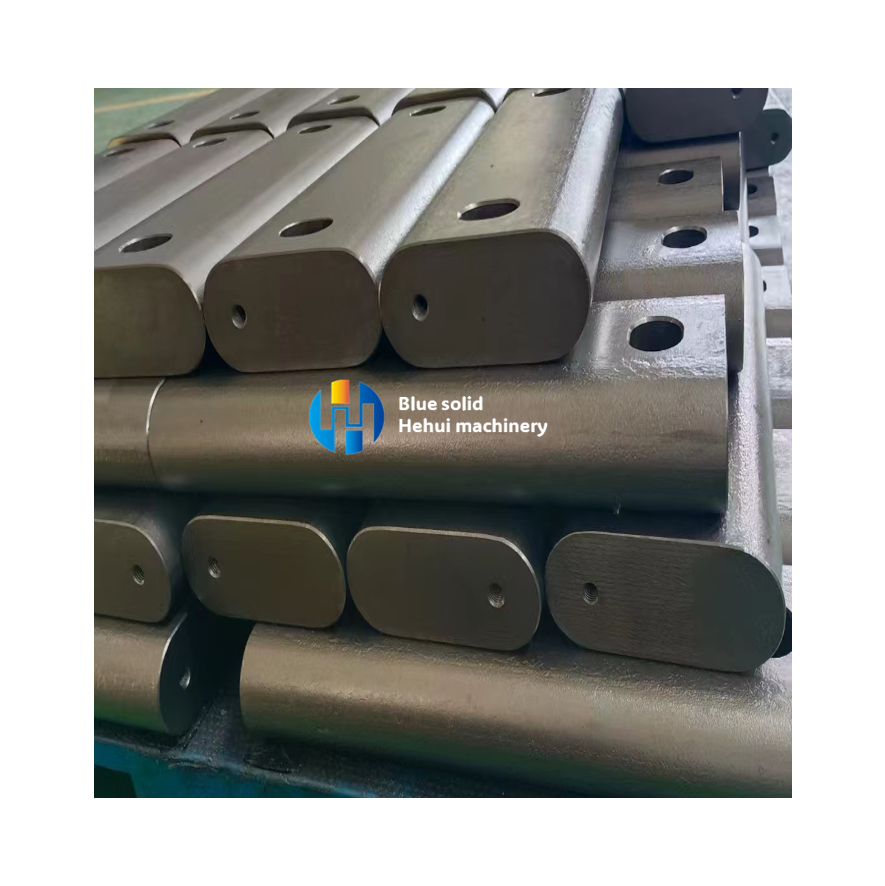

液压破碎锤中的连杆销在破碎过程中起着至关重要的作用,其功能主要包括以下几个方面:连接和固定:连杆销是连接破碎锤主体和破碎棒的关键部件,确保破碎棒能够牢固地固定在破碎锤主体上、通常情况下,一台破碎锤有四个杆销,它们共同作用将破碎杆固定在破碎锤主体上,使破碎锤能够产生高速冲击力。当破碎机开始工作时,电动机提供动力,液压系统控制破碎机运动,使破碎机的破碎棒反复高速冲击颚板,将物料破碎。 在此过程中,扁销承受巨大的冲击力和振动,有效地将破碎力传递给破碎棒,实现物料破碎。优质的扁销材料具有良好的耐磨性和抗冲击性,可以降低磨损和断裂的风险,延长使用寿命。同时,扁销的设计还需要考虑连接稳定性和传动效率,以确保破碎机能够高效稳定地工作。"维护和更换":由于在使用过程中会受到物料的冲击和磨损,因此需要定期检查和更换杆销。根据设备的使用频率和物料的破碎情况,可制定相应的更换周期,通常建议每 6 个月至 1 年更换一次。及时更换磨损的棒销,可确保破碎机的正常运行,避免因棒销断裂或失效而造成的停机损失、我们的杆销由高强度合金钢制成,并经过热处理,具有极高的硬度和耐磨性,可确保破碎作业的稳定性和可靠性。,photobank-6-2.png,photobank-7-3.png,photobank-8-3.png,photobank-9-4.png,photobank-10-4.png,photobank-11-3.png

Connection and fixation:

The rod pin is a key component that connects the main body of the breaker with the breaking bar, ensuring that the breaking bar can be firmly fixed to the main body of the breaker.

Typically, a breaker has four rod pins that work together to fix the breaking bar to the main body of the breaker, enabling the breaker to generate high-speed impact.

Transmission of crushing force:

The rod pin not only functions as a connector but also is responsible for transmitting the crushing force generated by the breaker. When the breaker starts working, the motor provides power, and the hydraulic system controls the movement of the breaker, causing the breaking bar of the breaker to repeatedly impact the jaw plate at high speed to crush the material.

During this process, the flat pin withstands significant impact force and vibration, effectively transmitting the crushing force to the breaking bar to achieve material crushing.

Improvement of crushing efficiency:

The material and design of the rod pin have a significant impact on the crushing efficiency of the breaker. High-quality flat pin materials with good abrasion resistance and impact resistance can reduce the risk of wear and breakage, extending the service life.

Meanwhile, the design of the flat pin also needs to consider connection stability and transmission efficiency to ensure that the breaker can work efficiently and stably.

Maintenance and replacement:

Due to the impact and wear caused by materials during use, the rod pin needs to be inspected and replaced regularly. Depending on the frequency of equipment use and material crushing conditions, a corresponding replacement cycle can be established, usually recommended to replace every 6 months to 1 year.

Timely replacement of worn rod pins can ensure the normal operation of the breaker and avoid downtime losses caused by broken or failed flat pins.

Our rod pins are made of high-strength alloy steel and undergo heat treatment to achieve extreme hardness and abrasion resistance, ensuring stability and reliability in crushing operations.

评价

目前还没有评价