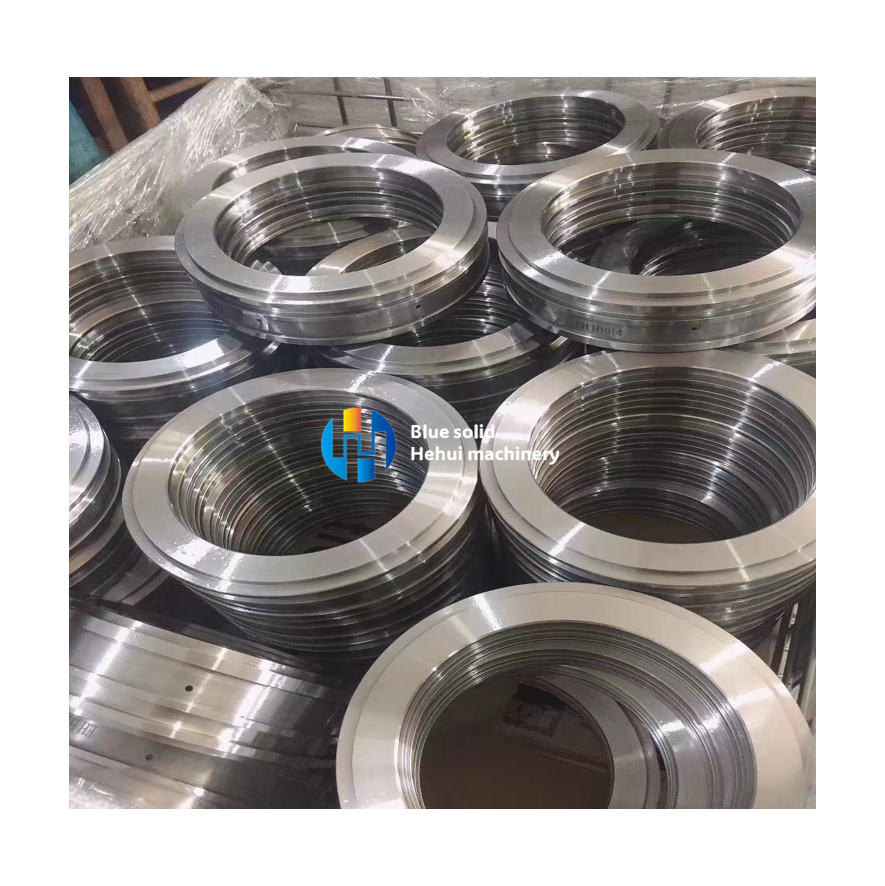

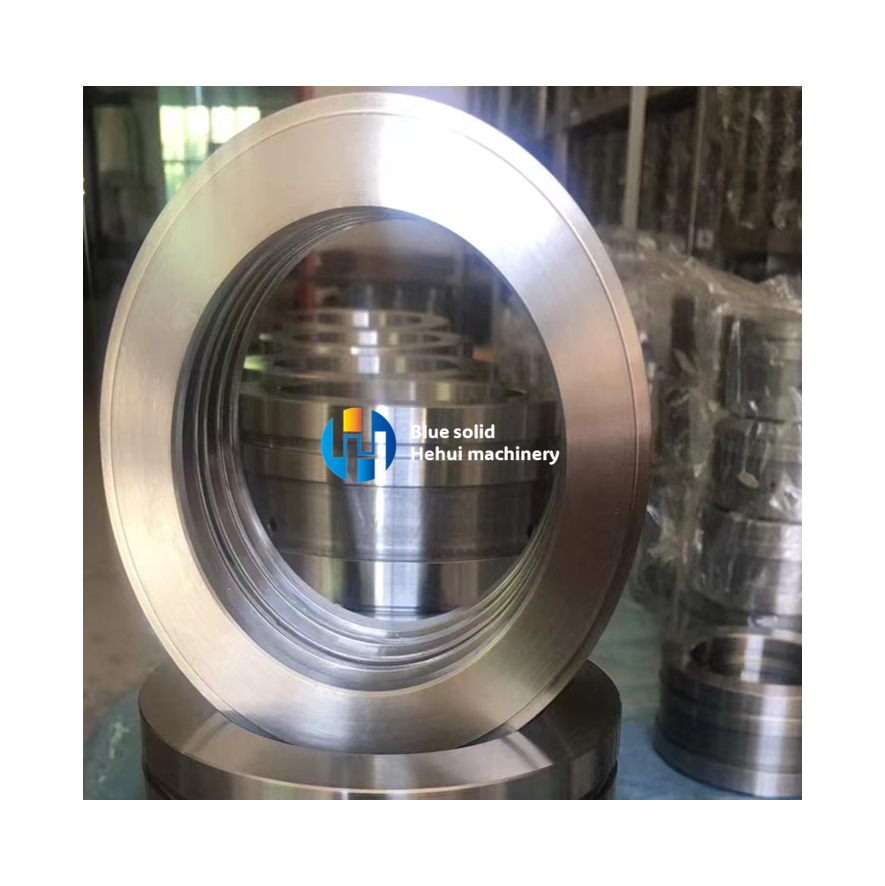

piston rings

The functions of piston rings in a hydraulic breaker mainly include the following aspects:

Sealing Function:

Piston rings serve as sealing elements between the piston and the cylinder, playing a crucial role in preventing air and oil leakage. This helps maintain the internal pressure and oil circulation of the hydraulic breaker, ensuring the normal and efficient operation of the equipment.

The sealing performance of the piston rings directly affects the working performance and service life of the breaker. Therefore, the mating conditions between the piston rings and the piston must meet the requirements to minimize gas leakage and improve thermal efficiency.

Protecting the Piston:

The sealing function of the piston rings can protect the piston, preventing wear between the piston and the cylinder, thus extending the service life of the breaker.

Regulating Oil:

Piston rings can also scrape off excess lubricating oil from the cylinder wall while leaving a thin oil film on the cylinder wall, ensuring normal lubrication for the cylinder, piston, and rings.

Heat Conduction:

Piston rings also play a role in heat conduction, transferring the heat generated by the piston to the cylinder liner, which acts as a cooling effect and helps maintain the stable operation of the equipment.

Guiding Function:

Piston rings play a certain guiding role in the operation of the piston, ensuring the normal operation of the breaker. At the same time, piston rings can also resist high temperatures and pressures inside the cylinder, maintaining the stability and reliability of the equipment.

Structural Characteristics:

In a breaker, piston rings are usually designed with three or four rings, which can improve sealing performance and wear resistance. Piston rings are typically made of high-quality cast iron with a smooth exterior and coated with lubricating oil to enhance sealing effect.

Reviews

There are no reviews yet.